In the world of technology, manufacturing, and communication, acronyms like SMT often pop up, leaving many wondering what they mean. Whether you’re a tech enthusiast, a professional in electronics, or just curious, this article will break down the meaning of SMT, its applications, and its significance in various industries.

What Does SMT Mean?

SMT stands for Surface Mount Technology. It is a method used in electronics manufacturing to mount components directly onto the surface of printed circuit boards (PCBs). Unlike traditional methods that require drilling holes for components, SMT allows for smaller, more efficient designs.

However, SMT can also have other meanings depending on the context, such as:

- Social Media Team: Refers to a group managing a brand’s social media presence.

- Synchronous Multi-Threading: A computing term related to processors.

- Sunday Morning Talk: A casual term for discussions or shows aired on Sunday mornings.

In this article, we’ll primarily focus on Surface Mount Technology, its applications, and its importance.

The Basics of Surface Mount Technology (SMT)

How Does SMT Work?

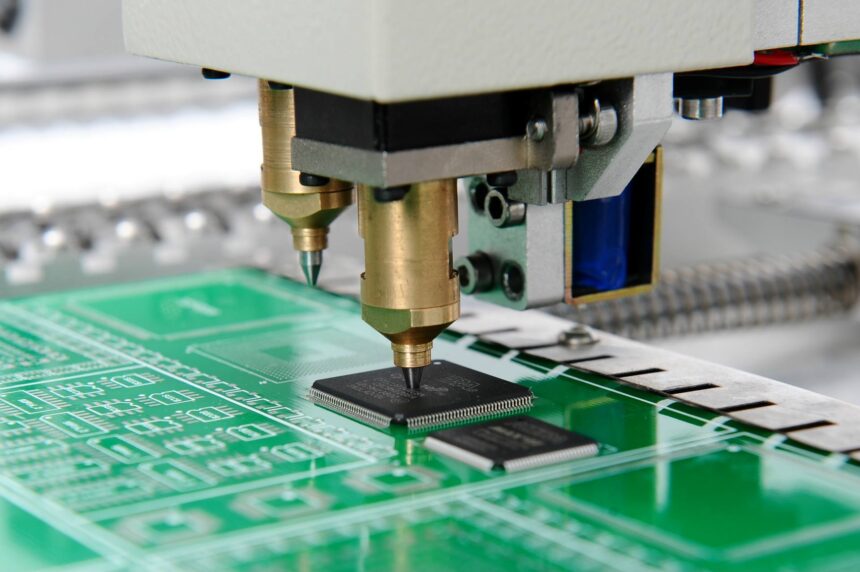

Surface Mount Technology involves attaching electronic components to the surface of a PCB using solder paste. The process typically includes:

- Solder Paste Application: A stencil is used to apply solder paste to specific areas of the PCB.

- Component Placement: Automated machines place components onto the solder paste.

- Reflow Soldering: The board is heated in a reflow oven, melting the solder paste and securing the components.

Advantages of SMT

- Compact Design: SMT allows for smaller and lighter devices.

- Cost-Effective: Reduces material and labor costs.

- High-Speed Production: Automated processes enable faster manufacturing.

- Improved Performance: Enhanced electrical performance due to shorter connections.

Common Components Used in SMT

| Component Type | Description |

|---|---|

| Resistors | Control current flow in circuits. |

| Capacitors | Store and release electrical energy. |

| Integrated Circuits | Miniaturized electronic circuits. |

| Diodes | Allow current to flow in one direction only. |

Applications of SMT

Surface Mount Technology is widely used in various industries, including:

1. Consumer Electronics

- Smartphones, laptops, and tablets rely heavily on SMT for compact and efficient designs.

- Wearable devices like smartwatches also use SMT components.

2. Automotive Industry

- Modern vehicles use SMT for advanced systems like GPS, sensors, and infotainment systems.

3. Medical Devices

- SMT enables the production of compact medical equipment, such as pacemakers and diagnostic tools.

4. Telecommunications

- Routers, modems, and other communication devices are manufactured using SMT.

Challenges of SMT

While SMT offers numerous benefits, it also comes with challenges:

- Complexity: Requires specialized equipment and expertise.

- Repair Difficulty: SMT components are smaller, making repairs more challenging.

- Thermal Stress: Components may be sensitive to high temperatures during soldering.

Other Meanings of SMT

As mentioned earlier, SMT can have different meanings depending on the context. Here are a few examples:

1. Social Media Team

- A group responsible for managing a brand’s social media strategy.

- Tasks include content creation, engagement, and analytics.

2. Synchronous Multi-Threading

- A technology used in processors to improve performance by executing multiple threads simultaneously.

- Commonly found in CPUs like Intel’s Hyper-Threading technology.

3. Sunday Morning Talk

- Refers to casual discussions or TV shows aired on Sunday mornings, often covering news or lifestyle topics.

Why Is SMT Important?

Surface Mount Technology has revolutionized the electronics industry by enabling:

- Miniaturization: Essential for modern gadgets and devices.

- Mass Production: Facilitates large-scale manufacturing with high precision.

- Innovation: Paves the way for advanced technologies like IoT and AI.

Frequently Asked Questions (FAQs)

1. What is the difference between SMT and THT?

- SMT (Surface Mount Technology): Components are mounted directly onto the PCB surface.

- THT (Through-Hole Technology): Components are inserted into drilled holes on the PCB.

2. Can SMT components be repaired?

- Yes, but it requires specialized tools and expertise due to the small size of the components.

3. Is SMT suitable for all types of electronics?

- SMT is ideal for compact and high-speed devices but may not be suitable for high-power applications.

Learn More About Technology Trends

For more insights into technology, manufacturing, and industry trends, visit TrendsMag. Our platform offers in-depth articles, guides, and updates to keep you informed.

Conclusion

Understanding the meaning of SMT and its applications is crucial for anyone involved in electronics or technology. From revolutionizing manufacturing processes to enabling the creation of modern gadgets, SMT plays a vital role in shaping the future.

Whether you’re exploring Surface Mount Technology or other contexts like Social Media Teams or Synchronous Multi-Threading, SMT is a term worth knowing. Stay updated with the latest trends and insights by visiting TrendsMag.